Add to Cart

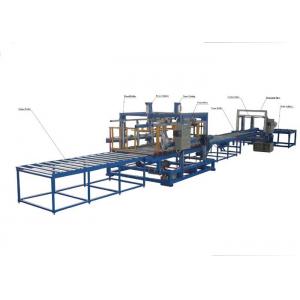

PLC Horizontal Continuous EPS Cutting Machine , EPS Production Line 4M

Option:

1. Automatic Wire Position System

2. Automatic Wastage Recycle System

Application:

Long EPS block continous cutting

Advantage:

Description:

The whole cutting line is composed as follows:

1. A Tilter (1) 2000mm length,800mm width

2. A Chain Conveyor (2) 8000mm length, 800mm width for Block Loading and centering operations

EPS board. It is drived by a SIEMENS AC motor which driven by a SIEMENS inverter.

3. A horizontal cutting station (3) for horizontal cutting. It is used to cut the foam block to requested

thickness.Are installed on horizontal cutting frame and tense with springs. The cutting voltage can be

adjusted to get the best cutting temperature for different foam density.

4. A vertical cutting station (5) for vertical cutting. It can cut the EPS boards to be different width and

trimming two sides.

5. A Roller Conveyor (6) 2000mm length, 800mm width for Block stock.

6. A down cutting station (7) to cut the EPS to requested length. A 10kVA transformer is use to heat the

wires. The cutting voltage can be adjusted to get the best cutting temperature for different foam density.

It has the Roller conveyor (8) length 4500mm, width 800mm also.

7. A Roller Conveyor (9) 4000mm length, 1300mm width for block output.

Specification:

| Model | 4m | |

| Control System | PLC | |

| Max. EPS Block | L4000*W1300*H1000mm | |

| Max. Number of Wires | Horizontal Cutting Station | 40pcs |

| Vertical Cutting Station | 15pcs | |

| Down Cutting Station | 20pcs | |

| Min. Cutting distance | Horizontal | 8mm |

| Down Cutting | 400mm | |

| Cutting Speed | 0~3m/min (Adjustable) | |

| Electrical requirements | 380V,50Hz,3phases | |

| Installed Power | 24kw | |

| Overall Dimension | L20500*W2500*H2950 mm | |

| Weight | 3280kgs | |

Finished products: